Share this

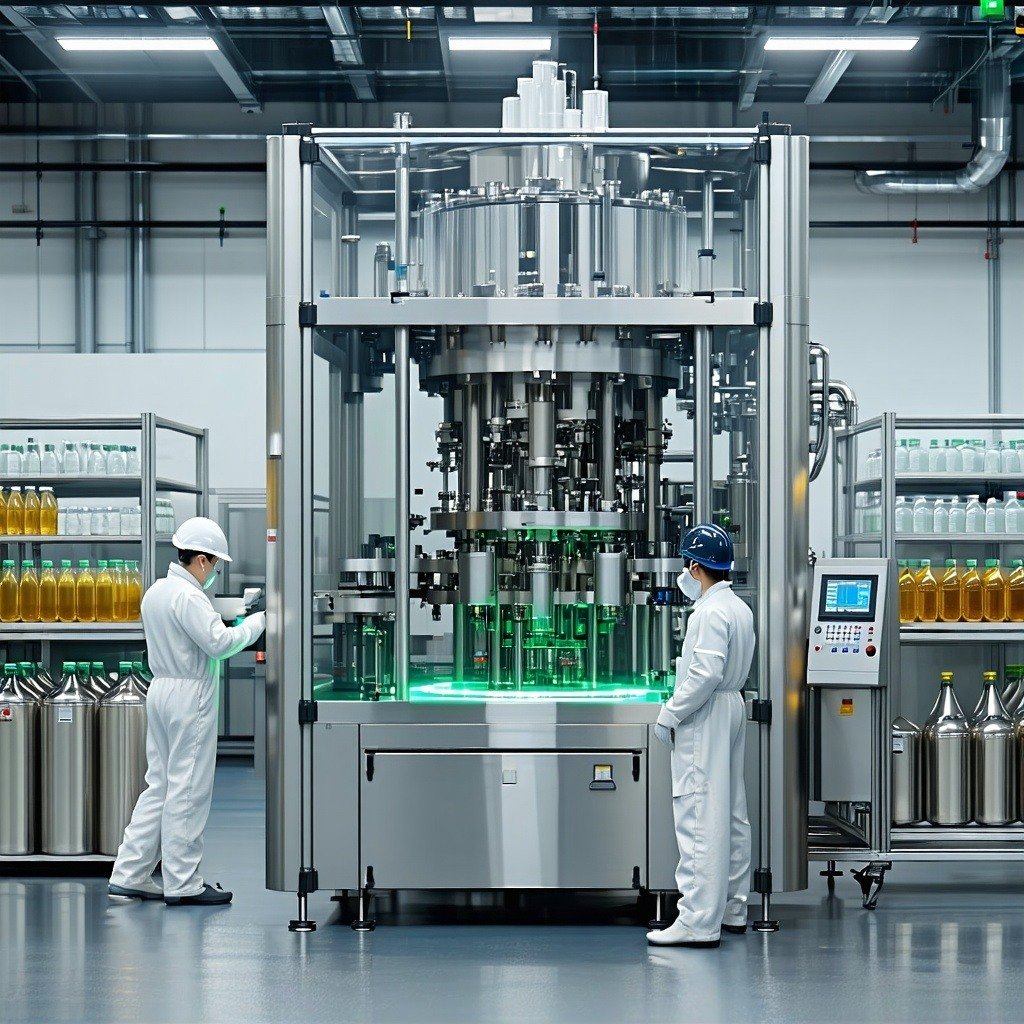

Apex Filling Systems: Expert Filling Solutions for the Oil & Petroleum Industry — Including Class I, Div 1 Capabilities

by APEX Filling Systems on Mar 28, 2025

In the oil and petroleum-based products industry, precision, durability, and safety aren’t just expectations—they're requirements. At Apex Filling Systems, we’ve built our reputation on delivering filling equipment that meets the unique challenges of petroleum-based products head-on. From motor oils to fuel additives, our machines are engineered to handle the toughest fluids in the harshest environments—and we do it with precision, reliability, and an unwavering commitment to safety.

Built for the Toughest Fluids in the Industry

Oil-based products pose unique filling challenges: high viscosities, volatile compounds, corrosive properties, and strict regulatory requirements. Apex systems are designed to perform in this demanding space, handling products such as:

-

Motor oils and lubricants

-

Hydraulic and transmission fluids

-

Greases and solvents

-

Fuel additives, degreasers, and specialty chemicals

Whether you're filling retail bottles or bulk industrial containers, we provide scalable solutions—ranging from semi-automatic machines to fully automated production lines—customized for your specific product and throughput needs.

Class I, Division 1 Filling Systems – Safety Comes Standard

Working with flammable or hazardous petroleum products requires specialized equipment built for explosion-proof environments. At Apex, we offer Class I, Division 1 rated filling systems, engineered specifically for hazardous locations where flammable gases or vapors may be present.

Our Class I, Div 1 machines feature:

-

Explosion-proof motors, sensors, and controls

-

Intrinsically safe system design

-

Sealed and corrosion-resistant components

-

Compliance with NEC, OSHA, and other safety standards

When safety and compliance are non-negotiable, Apex delivers peace of mind with robust, fully certified systems built to meet the strictest industrial requirements.

Engineered for Accuracy, Efficiency, and Longevity

Our piston fillers, gear pump systems, and flow meter technologies are ideal for high-viscosity, abrasive, or foamy fluids. Each system is built for consistent, accurate fills and long-term performance. With Apex, you get more than a machine—you get a finely tuned system that minimizes waste, maximizes uptime, and adapts with your production line as you grow.

Turnkey Support from Start to Finish

From consultation to installation and ongoing support, Apex works as an extension of your team. We don’t just sell machines—we build lasting partnerships. Our U.S.-based engineers and service technicians are here to ensure your equipment continues to perform reliably, safely, and efficiently for years to come.

Your Trusted Partner in Petroleum Product Filling

In an industry where downtime is expensive and product integrity is critical, Apex Filling Systems delivers. With deep experience in the petroleum sector and a full line of Class I, Div 1 capable equipment, we provide the dependable, scalable solutions your operation needs to thrive.

Let’s build a filling system that works as hard as you do. Contact us today to get started.

Share this

- Help First (81)

- Apex Filling Systems (53)

- Filling Equipment (51)

- Informational (47)

- Automatic Filling Machine (40)

- Industry Insights (38)

- Packaging Equipment (32)

- About Apex (20)

- Fillers (15)

- Automatic Capping (11)

- Apex Filling (10)

- Apex (7)

- American Made Goods (6)

- Uncategorized (5)

- Apex Team (3)

- Apex Family (2)

- Absolute Truth (1)

- Apex Way (1)

- Petroleum (1)

- oil (1)

- February 2026 (1)

- December 2025 (4)

- November 2025 (4)

- October 2025 (5)

- September 2025 (3)

- June 2025 (3)

- May 2025 (6)

- April 2025 (10)

- March 2025 (10)

- February 2025 (12)

- January 2025 (14)

- December 2024 (1)

- November 2024 (4)

- October 2024 (4)

- September 2024 (2)

- August 2024 (1)

- July 2024 (4)

- October 2022 (1)

- September 2022 (1)

- June 2022 (1)

- October 2021 (2)

- June 2021 (1)

- May 2021 (1)

- April 2021 (2)

- March 2021 (2)

- February 2021 (1)

- January 2021 (2)

- November 2020 (1)

- October 2020 (1)

- September 2020 (2)

- August 2020 (1)

- July 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (2)

- March 2020 (2)

- February 2020 (2)

- January 2020 (3)

- December 2019 (2)

- November 2019 (6)

- October 2019 (4)

- September 2019 (3)

- August 2019 (6)

- July 2019 (2)

- April 2019 (1)

- February 2019 (1)

- January 2019 (7)

- December 2018 (6)

- November 2018 (5)

- October 2018 (2)

- September 2018 (2)

- August 2018 (1)

- July 2018 (3)

- May 2018 (2)

- April 2018 (1)

- March 2018 (2)

- February 2018 (2)

- January 2018 (2)