Share this

Finding the Right Capping Solution

by Alicia Cannon on Feb 27, 2019

If you’ve been keeping up with our blogs, you know that finding the right liquid filling machine can be time consuming if you don’t have the help of experienced professionals. Luckily, getting a capping solution that’s the best fit for your business is a little bit easier.

Having a system to securely cap your bottles is incredibly important. It not only keeps your liquid fresh, but also keeps it sanitary and lets your customers know the container wasn’t tampered with prior to purchase.

What You Need to Know

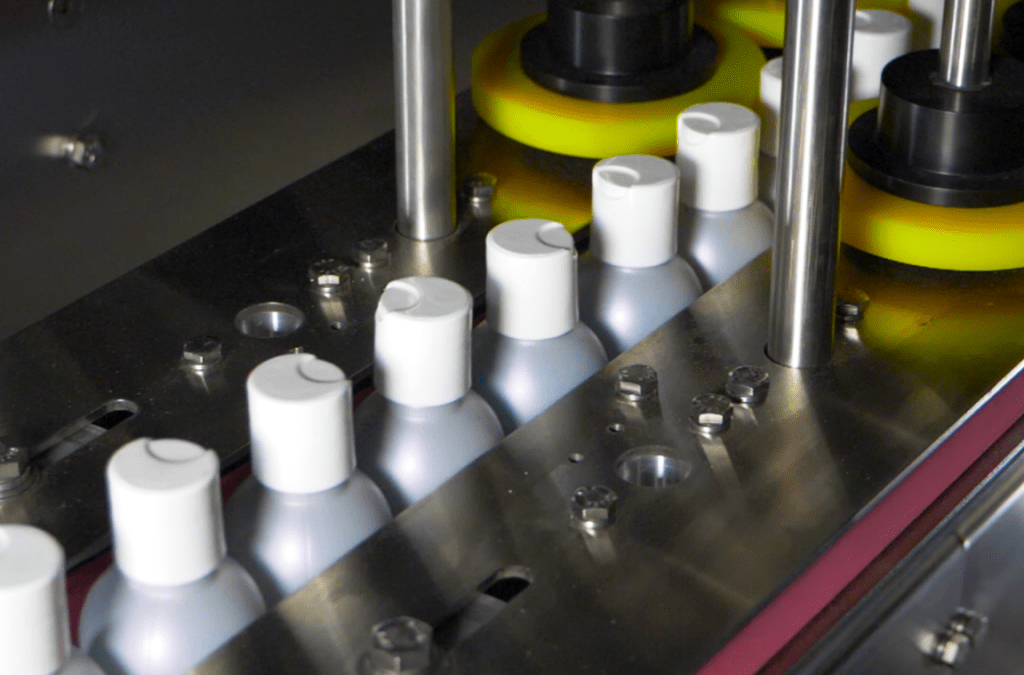

The first thing you need to think about when investing in a capping machine is choosing the closure design that will be used the packaging system. Some threaded closures are difficult to apply onto a container. As a result, it must have certain procedures to ensure that the cap is put on correctly. This is where a machine like a chuck capper might be useful.

Some capping solutions only work with certain sizes. So, if you have multiple different products with different size caps you may need more than one machine. There are also cap geometries that you need to think about. There are flat caps that work with pretty much any capping solution. However, there are also caps that are square and tall that are restricted to more limited options.

There are other factors you need to consider as well. This includes things like your workspace environment and production rate. You know your business the best. You need to decide how your solution will fit into your current operation. Oftentimes, this is best discussed with an experienced packaging professional. They can help you determine the best solution for your unique needs.

Why Work With Us?

Here at Apex, our goal is to fit our clients with the best possible capping solution for their needs. What makes us stand out from our competitors is our dedication to helping our customers succeed and our high-quality solutions. Our philosophy at Apex is that our customers are like our family. We wouldn’t recommend anything to you that we wouldn’t trust with our own loved ones.

We carry a wide variety of capping equipment to secure nearly any cap type onto a wide assortment of bottles. Our machines utilize the latest technologies to achieve the highest speeds and ensure correct cap completion. If you’re looking for a solution to improve the efficiency of your business, feel free to call us at 219-575-7493, email us at info@apexfilling.com or fill out our contact form here.

Alicia Cannon

Integrity, honesty, and a dedication to delivering ambitious results serve as the central themes of Alicia’s career and are evident in every interaction she has with our clients. Her relationship-centered leadership style has paved the way for Apex Filling System’s culture of compassion & empathy, executed with accountability that ensures consistently great outcomes. As a learner for life, her pursuit of continuous personal and professional growth has led Apex Filling Systems to be recognized as an industry innovator in customer experience. Holding advanced degrees in the areas of engineering and management, she has a unique ability to analyze processes, identify potential problems before they arise, and develop standardized solutions to ensure every client of Apex Filling Systems enjoys a hassle-free, professional, and pleasant experience. Her leadership style has been influenced by the work of some of the most well-regarded thought leaders throughout the last 50 years. Among them are Jim Collins, Sally Hogshead, John Maxwell, and Tony Robbins.

Share this

- Help First (82)

- Apex Filling Systems (54)

- Filling Equipment (52)

- Informational (48)

- Automatic Filling Machine (41)

- Industry Insights (39)

- Packaging Equipment (32)

- About Apex (20)

- Fillers (15)

- Automatic Capping (11)

- Apex Filling (10)

- Apex (7)

- American Made Goods (6)

- Uncategorized (5)

- Apex Team (3)

- Apex Family (2)

- Absolute Truth (1)

- Apex Way (1)

- Petroleum (1)

- oil (1)

- March 2026 (1)

- February 2026 (1)

- December 2025 (4)

- November 2025 (4)

- October 2025 (5)

- September 2025 (3)

- June 2025 (3)

- May 2025 (6)

- April 2025 (10)

- March 2025 (10)

- February 2025 (12)

- January 2025 (14)

- December 2024 (1)

- November 2024 (4)

- October 2024 (4)

- September 2024 (2)

- August 2024 (1)

- July 2024 (4)

- October 2022 (1)

- September 2022 (1)

- June 2022 (1)

- October 2021 (2)

- June 2021 (1)

- May 2021 (1)

- April 2021 (2)

- March 2021 (2)

- February 2021 (1)

- January 2021 (2)

- November 2020 (1)

- October 2020 (1)

- September 2020 (2)

- August 2020 (1)

- July 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (2)

- March 2020 (2)

- February 2020 (2)

- January 2020 (3)

- December 2019 (2)

- November 2019 (6)

- October 2019 (4)

- September 2019 (3)

- August 2019 (6)

- July 2019 (2)

- April 2019 (1)

- February 2019 (1)

- January 2019 (7)

- December 2018 (6)

- November 2018 (5)

- October 2018 (2)

- September 2018 (2)

- August 2018 (1)

- July 2018 (3)

- May 2018 (2)

- April 2018 (1)

- March 2018 (2)

- February 2018 (2)

- January 2018 (2)