Share this

4 Ways Tabletop Piston Fillers Help Your New Business Grow

by Alicia Cannon on Nov 19, 2018

Once you have developed the right liquid, gel or cream to sell – whether it’s essential oils, craft spirits, or hot sauce – you will need an efficient and hygienic way to bottle your product. As the owner of a growing business, you are probably not yet ready to invest in fully-automatic filling machinery. However, a semi-automatic tabletop piston filler will allow you to begin to automate your production at a low cost while only requiring a small amount of space.

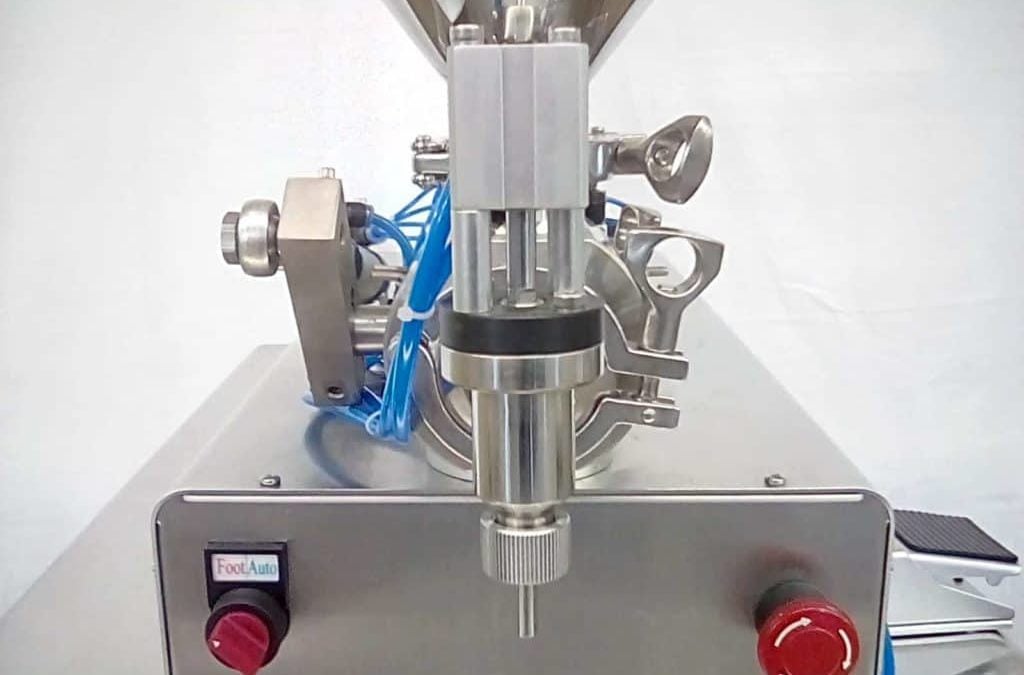

Piston fillers work by drawing a set amount of fluid from a larger supply into the piston chamber. It then then expels the product through the fill head into whatever container you have chosen for your product. With our tabletop piston filler, you operate the process with a foot pedal, leaving your hands free to position the container underneath the fill head, as illustrated in this video. This machine helps your business in the following ways:

Clean and Efficient Liquid Filling

Compared to filling liquids manually, a semi-automatic tabletop piston filler will turn an otherwise messy or frustrating process into one that is quick and efficient. This is due to their capacity to dispense any viscosity of liquid, with or without particles, in precise volumes. Imagine trying to pour a slow-moving syrup in precise quantities over and over. Or even dispensing a single ounce of an expensive essential oil into a very small vial. By hand, the process would take much longer and run the risk of product spillage. However, a piston filler can aim the liquid precisely into a narrow neck and dispense the correct amount automatically. This is done with bottom close positive shutoff nozzles to prevent any extra drips from escaping. The time saved and spills avoided alone make these machines valuable to your business.

Budget- and Space-Friendly Systems

Tabletop piston fillers are ideal for a home-based business that is ready to take the first steps toward automation without yet moving to a factory. The small footprint allows easy set-up in a garage or spare room, while still offering the quality of a professional packaging system. The lower cost of the equipment also allows business owners to grow in stages without risking too much capital in the beginning. Apex Filling has semi-automatic machines that start at $4,000, with options to expand and customize according to your needs.

With the Right Manufacturer: Easy Cleanup and Repairs

The components of well-made piston fillers are food grade and can be disassembled and cleaned easily. This is especially vital in the food and pharmaceutical industries. The time saved will add profit to your business. The cleanliness of the manufacturing environment will keep the trust of your customers. Lastly, the risk of cross-contamination of your ingredients will be reduced.

Because sometimes parts can break or wear down, you should also seek out a manufacturer that does the following. They should offer free phone support, a complete set of replacement parts already in stock for fast turnaround, and a dedication to their customers that lasts past the point of sale.

Ideally Suited for CBD, Essential Oil and Food and Beverage Industries

The demand for CBD tinctures and other CBD products is booming, with sales expected to reach $22 billion by 2020. In this rapidly expanding industry, business owners will need to react to the market quickly in order to compete. This means that choosing an involved and responsive manufacturer will be crucial. The precision of piston fillers is also vital to medical applications of these products. Customers will expect and require exact quantities of product when they make their purchases.

Essential oils are also a popular and growing market, with some pure oils costing several hundred dollars or more per ounce. The precise volume control piston fillers provide will help ensure that none of these substances are wasted. The ease with which our machines can be taken apart and cleaned also help prevent any inadvertent mixing of these potent oils.

In the food and beverage industry, packaging is a vital part of marketing. Our tabletop piston fillers work with all shapes of bottles and containers, with pistons available in sizes from 2 ml -5000 ml, enabling you to choose a container that will stand out on the shelves. They can also handle any viscosity, from flavored water to chunky salsa.

Let Apex Help You

Apex offers all of our clients customized solutions to their filling needs. To learn how we can help you begin automating your business, call us at 219-575-7493 or visit our page here.

Alicia Cannon

Integrity, honesty, and a dedication to delivering ambitious results serve as the central themes of Alicia’s career and are evident in every interaction she has with our clients. Her relationship-centered leadership style has paved the way for Apex Filling System’s culture of compassion & empathy, executed with accountability that ensures consistently great outcomes. As a learner for life, her pursuit of continuous personal and professional growth has led Apex Filling Systems to be recognized as an industry innovator in customer experience. Holding advanced degrees in the areas of engineering and management, she has a unique ability to analyze processes, identify potential problems before they arise, and develop standardized solutions to ensure every client of Apex Filling Systems enjoys a hassle-free, professional, and pleasant experience. Her leadership style has been influenced by the work of some of the most well-regarded thought leaders throughout the last 50 years. Among them are Jim Collins, Sally Hogshead, John Maxwell, and Tony Robbins.

Share this

- Help First (81)

- Apex Filling Systems (53)

- Filling Equipment (51)

- Informational (47)

- Automatic Filling Machine (40)

- Industry Insights (38)

- Packaging Equipment (32)

- About Apex (20)

- Fillers (15)

- Automatic Capping (11)

- Apex Filling (10)

- Apex (7)

- American Made Goods (6)

- Uncategorized (5)

- Apex Team (3)

- Apex Family (2)

- Absolute Truth (1)

- Apex Way (1)

- Petroleum (1)

- oil (1)

- February 2026 (1)

- December 2025 (4)

- November 2025 (4)

- October 2025 (5)

- September 2025 (3)

- June 2025 (3)

- May 2025 (6)

- April 2025 (10)

- March 2025 (10)

- February 2025 (12)

- January 2025 (14)

- December 2024 (1)

- November 2024 (4)

- October 2024 (4)

- September 2024 (2)

- August 2024 (1)

- July 2024 (4)

- October 2022 (1)

- September 2022 (1)

- June 2022 (1)

- October 2021 (2)

- June 2021 (1)

- May 2021 (1)

- April 2021 (2)

- March 2021 (2)

- February 2021 (1)

- January 2021 (2)

- November 2020 (1)

- October 2020 (1)

- September 2020 (2)

- August 2020 (1)

- July 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (2)

- March 2020 (2)

- February 2020 (2)

- January 2020 (3)

- December 2019 (2)

- November 2019 (6)

- October 2019 (4)

- September 2019 (3)

- August 2019 (6)

- July 2019 (2)

- April 2019 (1)

- February 2019 (1)

- January 2019 (7)

- December 2018 (6)

- November 2018 (5)

- October 2018 (2)

- September 2018 (2)

- August 2018 (1)

- July 2018 (3)

- May 2018 (2)

- April 2018 (1)

- March 2018 (2)

- February 2018 (2)

- January 2018 (2)