Share this

The Apex Guide to: Pump Fillers

by Alicia Cannon on Jul 31, 2020

Pump fillers bring the muscle to the most demanding, high-viscosity filling jobs, but they are also adaptable enough to meet the needs of a sole proprietor starting their business from home. Learn in this article how these sturdy yet affordable machines are different from piston fillers and gravity fillers, and how they can be the best choice for several different businesses.

The Pump Filler Difference

One notable feature of pump fillers is their ability to handle high-viscosity liquids and products with particulates (as well as even the thinnest liquids). For an entry-level operation, this can give you the versatility to use a single pump for nearly any liquid product.

Automatic pump fillers are also fast compared to most piston filling systems. They are often the choice for companies that want to fill heavy products at high quantities. (Even the semi-automatic tabletop fillers can increase the speed of production when compared with trying to fill containers neatly by hand.)

Finally, automatic pump fillers offer easier changeover between fill sizes, adding to their versatility. Semi-automatic pump fillers can handle a wide range of container sizes and heights.

Accuracy Under Pressure

Pump filling machines offer accurate volumetric fills in two different ways. A time-based fill uses a preset, adjustable amount of time for each fill cycle to dispense a consistent amount of liquid. A pulse-based fill measures out quantities based on a portion of movement, or multiple movements, of a pump component. The correct system to use depends on what you are trying to fill and other production specifications. Setting up time to consult with advisors will help you decide which type of fill is best for you.

What Liquids They Can Handle

Pump fillers can process all liquids, even down to more watery ones like CBD and essential oils, but they are especially well-suited for thicker products such as:

- cosmetic creams

- heavy sauces

- honey

- gels

- shampoos and conditioners

- paste cleaners

- car wax

- molten products

To facilitate the flow of some of the thicker or less homogeneous products, the fillers can be customized with features that heat, mix or agitate the supply to ensure that liquids with particulates are well-blended and stiffer products flow better. The drip-free, positive close fill heads ensure that the outside of the containers stay clean and no product is wasted.

These fillers also work well under special situations that include sanitary, hazardous, flammable, and corrosive products and environments.

Automatic or Tabletop Options

Semi-Automatic Tabletop Pump Fillers are entry-level machines that are well-suited for lower volume production requirements, including home-based startups. They are low cost and user friendly, allowing a single operator to fill containers ranging in volume from one ounce to one gallon. The compact design just needs to be plugged in (120VAC/60Hz), and it can be operated with the enclosed foot pedal. The high-quality filler is made in the USA, and it has a reliable, accurate, stainless steel gear pump, user selectable variable fill speeds and a cycle selector switch for semi-automatic or automatic modes.

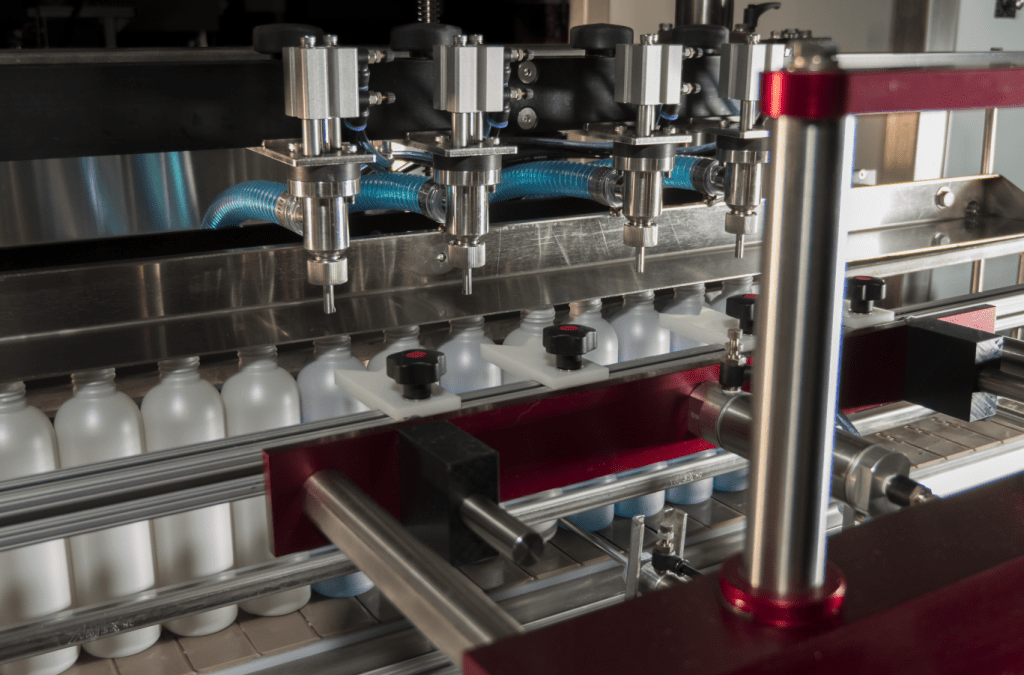

Automatic Pump Fillers are the choice for higher volume production, especially when thicker products need to be filled quickly. It has an Allen Bradley PLC and a user-friendly touch screen HMI. The pump speed on the automatic fillers can be adjusted electronically, and machines are available with 1 to 12 positive close fill heads. The stainless steel product reservoir has an automatic level control.

Similar to our other high-quality automatic fillers, these machines include:

- Pneumatic indexing gates

- No bottle/no fill sensor

- Bottle back up sensor (downstream) which delays filler operation until any jam is cleared

- On/off and speed controls for conveyance systems

- Front panel start and emergency stop

- Container counter

- Tool-free adjustment

- Upgradeable design

Customization Options

We are committed to helping you design the filling system that helps your business succeed. Customization options for our automatic pump fillers include:

- Automatic drip tray

- Bottle grabbers/neck grabbers

- Star wheel or timing screw indexing

- Hazardous location/environment construction – Class I, Division II, Group C&D

- Corrosion resistant construction, including all contact parts

- Heated stainless-steel tank

- Product agitation and mixing

- Diving heads

- Bottom-up filling

- Clean-in-place system

- Wash-down motors and controls

These automatic fillers will usually become part of a larger system which may include labeling, capping and conveyance solutions. These other machines might be purchased all at once, or a business might add them on gradually over time.

Let Apex Help You

Apex offers all of our clients customized solutions to their filling needs. Call us at 219-575-7493 or visit our page here to discuss the best equipment choices for you.

Alicia Cannon

Integrity, honesty, and a dedication to delivering ambitious results serve as the central themes of Alicia’s career and are evident in every interaction she has with our clients. Her relationship-centered leadership style has paved the way for Apex Filling System’s culture of compassion & empathy, executed with accountability that ensures consistently great outcomes. As a learner for life, her pursuit of continuous personal and professional growth has led Apex Filling Systems to be recognized as an industry innovator in customer experience. Holding advanced degrees in the areas of engineering and management, she has a unique ability to analyze processes, identify potential problems before they arise, and develop standardized solutions to ensure every client of Apex Filling Systems enjoys a hassle-free, professional, and pleasant experience. Her leadership style has been influenced by the work of some of the most well-regarded thought leaders throughout the last 50 years. Among them are Jim Collins, Sally Hogshead, John Maxwell, and Tony Robbins.

Share this

- Help First (81)

- Apex Filling Systems (53)

- Filling Equipment (51)

- Informational (47)

- Automatic Filling Machine (40)

- Industry Insights (38)

- Packaging Equipment (32)

- About Apex (20)

- Fillers (15)

- Automatic Capping (11)

- Apex Filling (10)

- Apex (7)

- American Made Goods (6)

- Uncategorized (5)

- Apex Team (3)

- Apex Family (2)

- Absolute Truth (1)

- Apex Way (1)

- Petroleum (1)

- oil (1)

- February 2026 (1)

- December 2025 (4)

- November 2025 (4)

- October 2025 (5)

- September 2025 (3)

- June 2025 (3)

- May 2025 (6)

- April 2025 (10)

- March 2025 (10)

- February 2025 (12)

- January 2025 (14)

- December 2024 (1)

- November 2024 (4)

- October 2024 (4)

- September 2024 (2)

- August 2024 (1)

- July 2024 (4)

- October 2022 (1)

- September 2022 (1)

- June 2022 (1)

- October 2021 (2)

- June 2021 (1)

- May 2021 (1)

- April 2021 (2)

- March 2021 (2)

- February 2021 (1)

- January 2021 (2)

- November 2020 (1)

- October 2020 (1)

- September 2020 (2)

- August 2020 (1)

- July 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (2)

- March 2020 (2)

- February 2020 (2)

- January 2020 (3)

- December 2019 (2)

- November 2019 (6)

- October 2019 (4)

- September 2019 (3)

- August 2019 (6)

- July 2019 (2)

- April 2019 (1)

- February 2019 (1)

- January 2019 (7)

- December 2018 (6)

- November 2018 (5)

- October 2018 (2)

- September 2018 (2)

- August 2018 (1)

- July 2018 (3)

- May 2018 (2)

- April 2018 (1)

- March 2018 (2)

- February 2018 (2)

- January 2018 (2)