Share this

Spindle Tightener Guide - Apex Filling

by Alicia Cannon on Nov 02, 2020

Spindle Tightener Guide

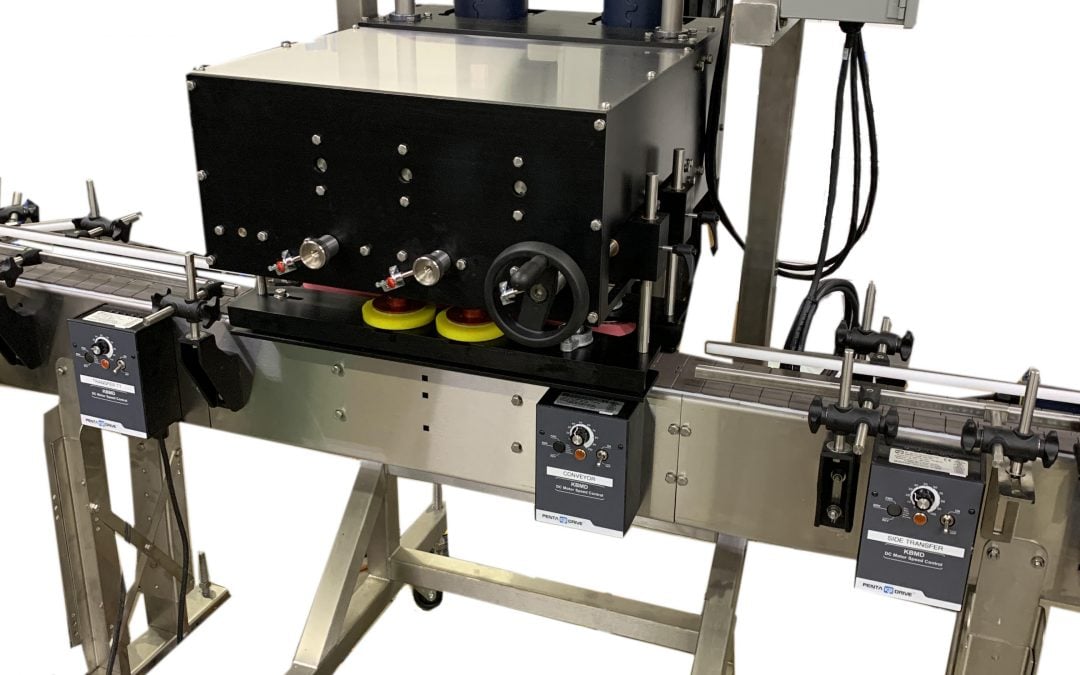

Spindle tighteners are closely integrated with spindle cappers to securely tighten caps on containers efficiently. The mechanical process needed to twist a cap onto a bottle is one that a person can perform without much thought, but to recreate the motions with machines requires a finely tuned balance of torque, speed and careful positioning of different components. The resulting increase in productivity, however, makes automating the process of tightening caps well worth the effort of making the initial adjustments.

How They Work:

After caps are positioned on top of the necks of containers, the spindle tightener uses gripper belts to draw the containers forward as the spindle wheels tighten the caps to the correct level of torque.

The Versatility of Spindle Tighteners

Spindle tighteners can handle almost any bottle type or shape including PET, PP, PVC, HDPE, LDPE, and glass. Because of their modular design, you can use them as the foundation of a simple capping system – adding just a cap tightener at first – and then over time add other automation capabilities such as a chute or automatic cap feeder as needed. In conjunction with a spindle capper, spindle tighteners can process over 50 bottles per minute.

Precision and Efficiency

Spindle tighteners assist in positioning bottles and applying the correct amount of torque to caps to ensure that containers are sealed securely, protecting the contents. This requires different components to operate together, while allowing for precise adjustments to be made depending on the specific needs of each job. These components include:

Gripper belts: Gripper belts hold the bottles in place as they are moved through the spindle capper. Spindle tighteners may use a single set of gripper belts for bottles with a simple shape, or a double set of belts for tall or irregularly shaped containers. The height of the belt placement is important for keeping the bottles stable, as belts that are set too low can allow wobbling, while belts set too close to the neck can prevent a good seal from forming.

The tension of the gripper belts also needs to be adjusted to the size of the bottles, as too much pressure can damage the bottles and too little pressure will allow too much movement.

Spindle wheels: Working in sets of 4, 6 or 8 matched spinning disks, the spindle wheels use the balance of speed and tension to create the motions needed to tighten a cap onto a bottle. Automating this process prevents the repetitive strain injury that a human capper would experience, while greatly increasing productivity and consistency. The functions of cappers and tighteners work together most closely at this stage.

When more than a single matched set of spindle wheels are used, each one will be set slightly lower than the one before it to account for the downward-spiraling movement of the cap as it is tightened on the bottle threads. As with gripper belts, too much tension can cause damage to the packaging, and too little tension will fail to tighten the caps sufficiently.

The settings for both gripper belts and spindle wheels can be easily adjusted by an operator to accommodate different jobs. The team at Apex is also on hand to help you determine which settings work best with your containers.

Industry Applications

- Personal care

- Nutraceuticals

- Cosmetics

- Beverages

- Pharmaceuticals

- Household chemicals

- Petroleum products

Features

- Heavy-duty 304SS free standing frame

- Easy integration with most conveyor configurations

- Variable speed industrial grade motors

- 4, 6 or 8 spindle wheels

- Spindle wheel adjustment knobs with locks

- Gripper belt height and width adjustment

- Removable dual gripper belts on 6 and 8 spindle models

- No change parts required for a wide range of containers

- 303 stainless steel drive shafts and adjustment support shafts

- Adjustable spindle clutches on final set of tightening spindles

- Power height adjustment available on 6 and 8 spindle models

- Tool-free changeover

- Made in the USA

Customization Options

Additional options include:

- Cap sorting device – vibratory bowl

- Cap sorting device – centrifugal bowl

- Cap sorting device – sorting elevator

- Trigger sprayer cap rails

- F-style spacer

- Reversible first spindle set (on 8-spindle capper)

- Dual gripper belts

- Hazardous location/environment construction – Class I, Division II, Groups C&D

The Apex team will also be on hand to assist with the maintenance of all of our packaging solutions, including providing replacement parts, troubleshooting, and readjusting controls to accommodate different containers. Feel free to reach out to us if you have any questions regarding the spindle tightener guide.

Let Apex Help You

Apex offers all of our clients customized solutions to their filling and capping needs. Call us at 219-575-7493 or visit our page here to discuss the best equipment choices for you.

Alicia Cannon

Integrity, honesty, and a dedication to delivering ambitious results serve as the central themes of Alicia’s career and are evident in every interaction she has with our clients. Her relationship-centered leadership style has paved the way for Apex Filling System’s culture of compassion & empathy, executed with accountability that ensures consistently great outcomes. As a learner for life, her pursuit of continuous personal and professional growth has led Apex Filling Systems to be recognized as an industry innovator in customer experience. Holding advanced degrees in the areas of engineering and management, she has a unique ability to analyze processes, identify potential problems before they arise, and develop standardized solutions to ensure every client of Apex Filling Systems enjoys a hassle-free, professional, and pleasant experience. Her leadership style has been influenced by the work of some of the most well-regarded thought leaders throughout the last 50 years. Among them are Jim Collins, Sally Hogshead, John Maxwell, and Tony Robbins.

Share this

- Help First (81)

- Apex Filling Systems (53)

- Filling Equipment (51)

- Informational (47)

- Automatic Filling Machine (40)

- Industry Insights (38)

- Packaging Equipment (32)

- About Apex (20)

- Fillers (15)

- Automatic Capping (11)

- Apex Filling (10)

- Apex (7)

- American Made Goods (6)

- Uncategorized (5)

- Apex Team (3)

- Apex Family (2)

- Absolute Truth (1)

- Apex Way (1)

- Petroleum (1)

- oil (1)

- February 2026 (1)

- December 2025 (4)

- November 2025 (4)

- October 2025 (5)

- September 2025 (3)

- June 2025 (3)

- May 2025 (6)

- April 2025 (10)

- March 2025 (10)

- February 2025 (12)

- January 2025 (14)

- December 2024 (1)

- November 2024 (4)

- October 2024 (4)

- September 2024 (2)

- August 2024 (1)

- July 2024 (4)

- October 2022 (1)

- September 2022 (1)

- June 2022 (1)

- October 2021 (2)

- June 2021 (1)

- May 2021 (1)

- April 2021 (2)

- March 2021 (2)

- February 2021 (1)

- January 2021 (2)

- November 2020 (1)

- October 2020 (1)

- September 2020 (2)

- August 2020 (1)

- July 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (2)

- March 2020 (2)

- February 2020 (2)

- January 2020 (3)

- December 2019 (2)

- November 2019 (6)

- October 2019 (4)

- September 2019 (3)

- August 2019 (6)

- July 2019 (2)

- April 2019 (1)

- February 2019 (1)

- January 2019 (7)

- December 2018 (6)

- November 2018 (5)

- October 2018 (2)

- September 2018 (2)

- August 2018 (1)

- July 2018 (3)

- May 2018 (2)

- April 2018 (1)

- March 2018 (2)

- February 2018 (2)

- January 2018 (2)