Share this

The Future of Liquid Filling: How Automatic Filling Machines are Transforming the Packaging Industry

by Alicia Cannon on Nov 11, 2024

Introduction:

In recent years, the packaging industry has seen remarkable advancements with the introduction of automatic filling machines and industrial filling systems. From food and beverage to distilled spirits, these automated filling machines are playing a pivotal role in driving efficiency, reducing costs, and ensuring high-quality production. But with so many options in filling and capping solutions, how can businesses select the best bottle filling equipment to meet their needs?

1. Why Automatic Filling Machines Are a Game-Changer:

The benefits of automatic filling machines go beyond simple automation. For small businesses and large manufacturers alike, inline filling systems allow for high-speed, accurate filling of liquids into bottles and containers, meeting rigorous industry standards. These systems not only cut down on labor costs but also improve overall production quality and consistency.

- Key takeaway: Learn how the best automatic filling machines for liquids can help your business stay competitive and sustainable in a rapidly evolving market.

2. Industry-Specific Applications for Filling Machines:

Whether you're in the food and beverage industry, handling chemicals, or working with whiskey and distilled spirits, there’s an ideal liquid filling machine for every application. Here’s how these industrial filling systems are tailored to specific needs:

- Food and Beverage Filling Machines: Designed to handle both thick and thin liquids with precision.

- Distilled Spirits Filling Equipment: Built to maintain product integrity, precise volume control, and meet legal standards for alcoholic beverages.

- Chemical Filling Machines: Engineered to withstand corrosive substances and ensure safety.

3. Flexible, Efficient, and Reliable: Top Features of Today’s Filling Machines:

A look at the must-have features in reliable filling solutions:

- Customizable filling options that cater to a variety of products.

- High-speed inline systems for mass production without sacrificing quality.

- Turnkey filling solutions for businesses seeking an all-in-one approach to packaging.

4. Choosing the Right Filling and Capping Equipment for Your Business:

Selecting the right filling machines for small businesses can be challenging, especially when considering future growth. Here’s a guide on how to pick affordable filling machines that still meet high standards of efficiency and durability. Look for flexible packaging machinery that can scale with your business needs, ensuring a reliable long-term investment.

5. Energy Efficiency and Sustainability in Filling Equipment:

Today’s energy-efficient filling equipment solutions are designed not only to reduce costs but also to minimize environmental impact. Discover how user-friendly bottle filling equipment can benefit your bottom line while supporting your commitment to sustainability.

Conclusion:

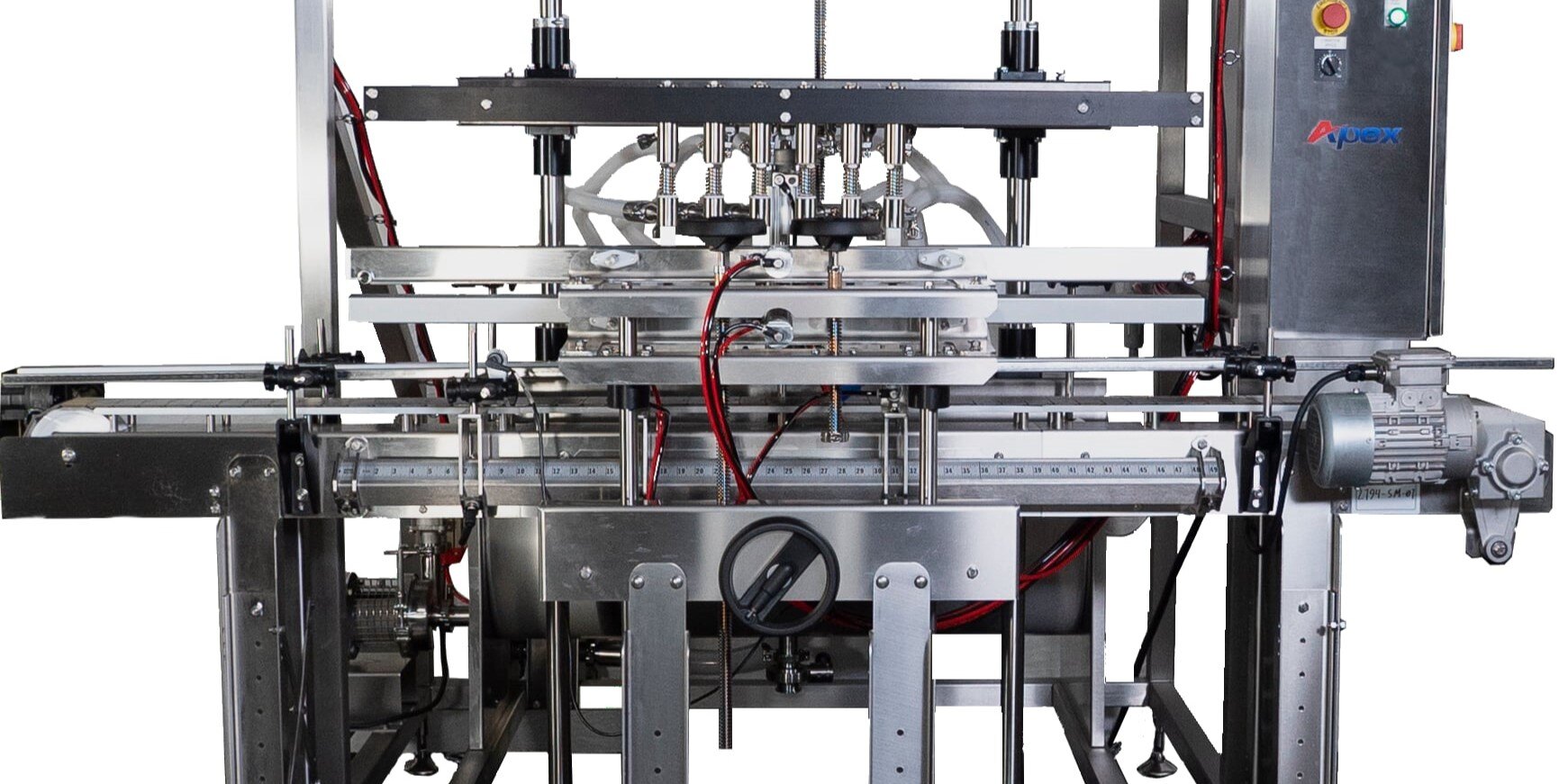

The world of automatic filling and capping machines is evolving quickly, providing businesses with innovative, adaptable, and customizable filling machines that meet today’s demands for efficiency and reliability. Whether you need filling machines for plastic bottles or an automated packaging line, choosing the right equipment is key to staying competitive. At Apex Filling Systems, we offer a range of affordable, durable, and high-speed filling machines tailored to industry needs.

Share this

- Help First (81)

- Apex Filling Systems (53)

- Filling Equipment (51)

- Informational (47)

- Automatic Filling Machine (40)

- Industry Insights (38)

- Packaging Equipment (32)

- About Apex (20)

- Fillers (15)

- Automatic Capping (11)

- Apex Filling (10)

- Apex (7)

- American Made Goods (6)

- Uncategorized (5)

- Apex Team (3)

- Apex Family (2)

- Absolute Truth (1)

- Apex Way (1)

- Petroleum (1)

- oil (1)

- February 2026 (1)

- December 2025 (4)

- November 2025 (4)

- October 2025 (5)

- September 2025 (3)

- June 2025 (3)

- May 2025 (6)

- April 2025 (10)

- March 2025 (10)

- February 2025 (12)

- January 2025 (14)

- December 2024 (1)

- November 2024 (4)

- October 2024 (4)

- September 2024 (2)

- August 2024 (1)

- July 2024 (4)

- October 2022 (1)

- September 2022 (1)

- June 2022 (1)

- October 2021 (2)

- June 2021 (1)

- May 2021 (1)

- April 2021 (2)

- March 2021 (2)

- February 2021 (1)

- January 2021 (2)

- November 2020 (1)

- October 2020 (1)

- September 2020 (2)

- August 2020 (1)

- July 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (2)

- March 2020 (2)

- February 2020 (2)

- January 2020 (3)

- December 2019 (2)

- November 2019 (6)

- October 2019 (4)

- September 2019 (3)

- August 2019 (6)

- July 2019 (2)

- April 2019 (1)

- February 2019 (1)

- January 2019 (7)

- December 2018 (6)

- November 2018 (5)

- October 2018 (2)

- September 2018 (2)

- August 2018 (1)

- July 2018 (3)

- May 2018 (2)

- April 2018 (1)

- March 2018 (2)

- February 2018 (2)

- January 2018 (2)