Share this

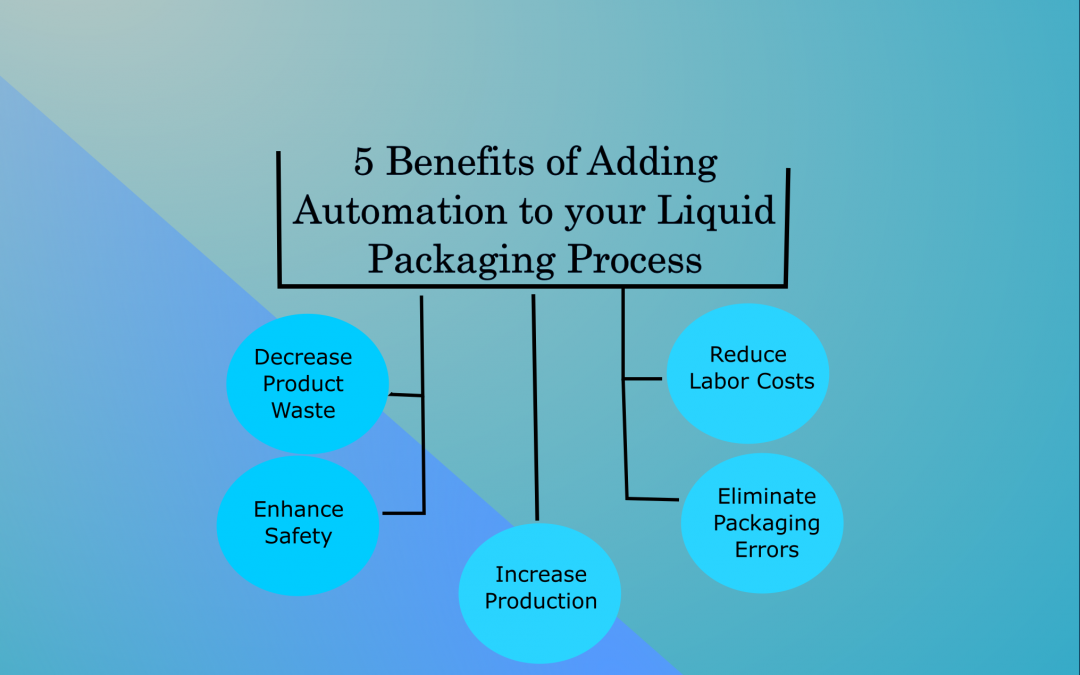

5 Reasons to Add Automation to Your Liquid Packaging Process

by Alicia Cannon on Sep 06, 2022

If you’re in the business of packaging liquids, you know that it can be a challenging and time-consuming process. From ensuring that each container is filled to the correct level to ensuring that the labels are applied correctly, there’s a lot that can go wrong. That’s why more and more companies are turning to automation to help streamline their packing processes and increase efficiency. Here are just a few of the benefits that you can enjoy by adding automation to your liquid packaging process.

1. Decrease Product Waste:

One of the biggest benefits of automating your liquid packaging process is that it can help decrease product waste. When you’re filling containers by hand, it’s easy to overfill or underfill them, leading to wasted product. However, automated liquid fillers are able to dispense the exact amount of liquid into each container every time, eliminating product waste.

2. Enhance Safety:

Automated machines also enhance safety by reducing the possibility of injuries on the job. OSHA reports that packaging operations are one of the most dangerous types of manufacturing jobs, so incorporating automation can help keep your employees safe.

3. Reduce Labor Costs:

In addition to decreasing product waste and enhancing safety, automating your liquid packaging process can also help reduce labor costs. When you’re filling containers by hand, you need to have multiple employees on the line in order to keep up with demand. However, when you use automated machinery, you can do more with less. This helps to improve your bottom line by reducing labor costs.

4. Eliminate Packaging Errors:

Another advantage of automation is that it can help eliminate errors in your packaging process. If labels are applied incorrectly or containers are not filled to the correct level, it can lead to products being rejected by customers or returned back to your facility. But with an automated machine, you can rest assured knowing that each container will be filled and labeled correctly every time.

5. Increase Production:

Finally, automating your liquid packaging process can also help increase production. When you’re filling containers by hand, there’s a limit to how many containers you can fill in a day due to the amount of time it takes to do so manually. However, when you use automated machinery, you’re able to fill more containers in a shorter amount of time because the machines can work faster than humans can. This allows you to meet customer demand in a timely manner and keep up with competitors who may be using similar automated technologies.

As you can see, there are many benefits to automating your liquid packaging process. From decreased product waste and enhanced safety to reduced labor costs and increased production, automating your process can help improve your bottom line in many ways. If you’re looking for a way to improve your business, consider adding automation to your liquid packaging process today!

Alicia Cannon

Integrity, honesty, and a dedication to delivering ambitious results serve as the central themes of Alicia’s career and are evident in every interaction she has with our clients. Her relationship-centered leadership style has paved the way for Apex Filling System’s culture of compassion & empathy, executed with accountability that ensures consistently great outcomes. As a learner for life, her pursuit of continuous personal and professional growth has led Apex Filling Systems to be recognized as an industry innovator in customer experience. Holding advanced degrees in the areas of engineering and management, she has a unique ability to analyze processes, identify potential problems before they arise, and develop standardized solutions to ensure every client of Apex Filling Systems enjoys a hassle-free, professional, and pleasant experience. Her leadership style has been influenced by the work of some of the most well-regarded thought leaders throughout the last 50 years. Among them are Jim Collins, Sally Hogshead, John Maxwell, and Tony Robbins.

Share this

- Help First (81)

- Apex Filling Systems (53)

- Filling Equipment (51)

- Informational (47)

- Automatic Filling Machine (40)

- Industry Insights (38)

- Packaging Equipment (32)

- About Apex (20)

- Fillers (15)

- Automatic Capping (11)

- Apex Filling (10)

- Apex (7)

- American Made Goods (6)

- Uncategorized (5)

- Apex Team (3)

- Apex Family (2)

- Absolute Truth (1)

- Apex Way (1)

- Petroleum (1)

- oil (1)

- February 2026 (1)

- December 2025 (4)

- November 2025 (4)

- October 2025 (5)

- September 2025 (3)

- June 2025 (3)

- May 2025 (6)

- April 2025 (10)

- March 2025 (10)

- February 2025 (12)

- January 2025 (14)

- December 2024 (1)

- November 2024 (4)

- October 2024 (4)

- September 2024 (2)

- August 2024 (1)

- July 2024 (4)

- October 2022 (1)

- September 2022 (1)

- June 2022 (1)

- October 2021 (2)

- June 2021 (1)

- May 2021 (1)

- April 2021 (2)

- March 2021 (2)

- February 2021 (1)

- January 2021 (2)

- November 2020 (1)

- October 2020 (1)

- September 2020 (2)

- August 2020 (1)

- July 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (2)

- March 2020 (2)

- February 2020 (2)

- January 2020 (3)

- December 2019 (2)

- November 2019 (6)

- October 2019 (4)

- September 2019 (3)

- August 2019 (6)

- July 2019 (2)

- April 2019 (1)

- February 2019 (1)

- January 2019 (7)

- December 2018 (6)

- November 2018 (5)

- October 2018 (2)

- September 2018 (2)

- August 2018 (1)

- July 2018 (3)

- May 2018 (2)

- April 2018 (1)

- March 2018 (2)

- February 2018 (2)

- January 2018 (2)